Oct 10,2023

Die casting has long been a cornerstone of the automotive manufacturing process. It's a technique that enables the production of complex, high-precision automotive parts with remarkable efficiency. As the automotive industry continually evolves, so does die casting.

In this blog post, we will explore the future of die casting in the automotive sector, highlighting its evolution, benefits, sustainability aspects, cutting-edge technologies, and the challenges it faces. Moreover, we will delve into case studies that showcase the real-world impact of die casting in the automotive industry.

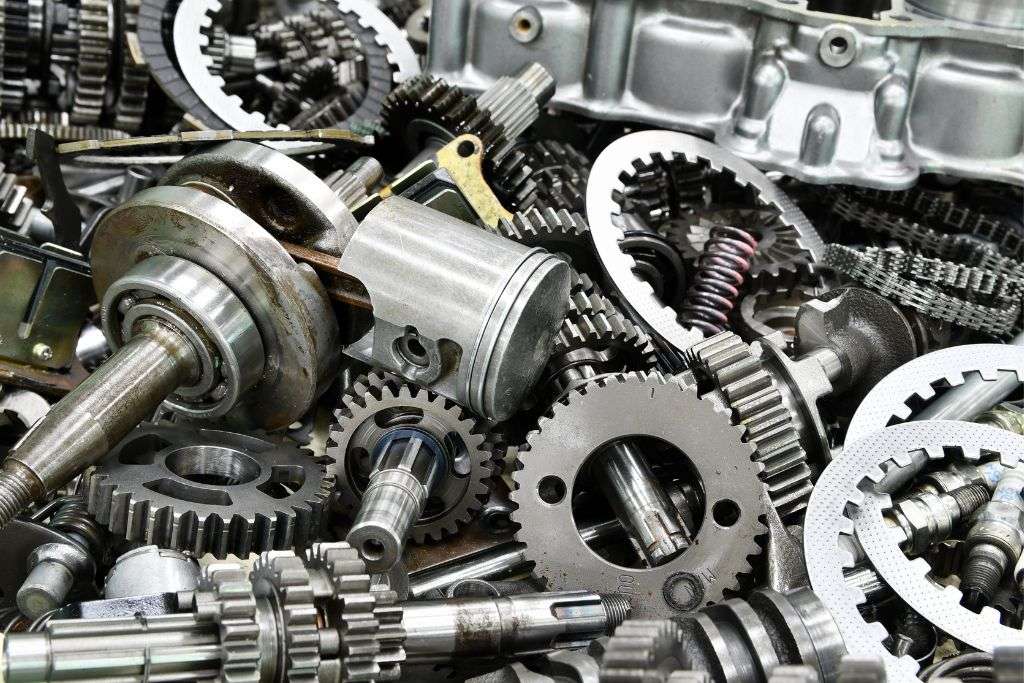

Die casting is a manufacturing process that involves injecting molten metal into a mold cavity to create a precisely shaped component. In the automotive industry, die casting is instrumental in producing a wide range of parts, from engine components to structural elements. As we explore the future of die casting in this dynamic sector, we will uncover its enduring relevance and potential for growth.

Die casting has deep roots in the automotive industry. It emerged as a crucial production method in the early 20th century, revolutionizing the way automobile components were manufactured. The ability to produce intricate parts with consistent quality paved the way for automotive mass production.

Over the years, die casting technology has seen significant advancements. Innovations in mold design, materials, and process control have allowed for greater precision and efficiency. The advent of aluminum and magnesium alloys has expanded the range of applications for die casting, making it an even more indispensable manufacturing method.

Customization has become a key driver of die casting in the automotive industry. Manufacturers now have the capability to tailor die casting processes to meet specific design requirements, resulting in highly customized automotive parts.

Die casting offers several key benefits that make it a preferred choice in the automotive sector:

Die casting ensures high precision and consistency in component manufacturing, which is crucial for automotive safety and performance.

The efficiency of die casting leads to cost savings, making it an attractive option for automotive manufacturers seeking to optimize their production processes.

Die casting is a fast and efficient process, allowing for quick production turnaround times to meet the demands of the automotive market.

Customization is at the core of die casting's appeal in the automotive industry. It enables the creation of unique, tailor-made components that meet the exact specifications of the vehicle design.

Die casting also aligns with the automotive industry's growing focus on sustainability:

Die casting allows for the use of recyclable materials, reducing the environmental impact of automotive manufacturing.

The ability to recycle and reuse materials in die casting contributes to sustainability efforts by minimizing waste.

Die casting generates fewer emissions compared to some alternative manufacturing methods, making it a greener option for automotive production.

The future of die casting in the a

Automotive industry is closely tied to technological advancements:

Computer simulations and modeling techniques are increasingly used to optimize die casting processes, improving efficiency and reducing waste.

Automation is becoming more prevalent in die casting facilities, further enhancing precision and productivity.

The integration of die casting with other automotive manufacturing processes is driving innovation and efficiency in the industry.

As we peer into the future, several trends and predictions emerge:

The rise of electric vehicles is poised to have a significant impact on die casting. EVs require specialized components and die casting is well-suited to meet these demands.

The fourth industrial revolution, characterized by connectivity and data-driven decision-making, will play a pivotal role in shaping the future of die casting in the automotive sector.

Die casting faces certain challenges in the automotive industry, including increased demand for sustainability and the need for more advanced materials. However, these challenges are met with innovative solutions, such as the development of new alloys and improved recycling practices.

The future of die casting in the automotive industry is bright and promising. With ongoing technological advancements, a focus on sustainability, and a commitment to customization, die casting will continue to be a driving force in the production of high-quality automotive components.

As the automotive industry evolves, so too will die casting, ensuring its enduring relevance in the ever-changing landscape of automotive manufacturing.